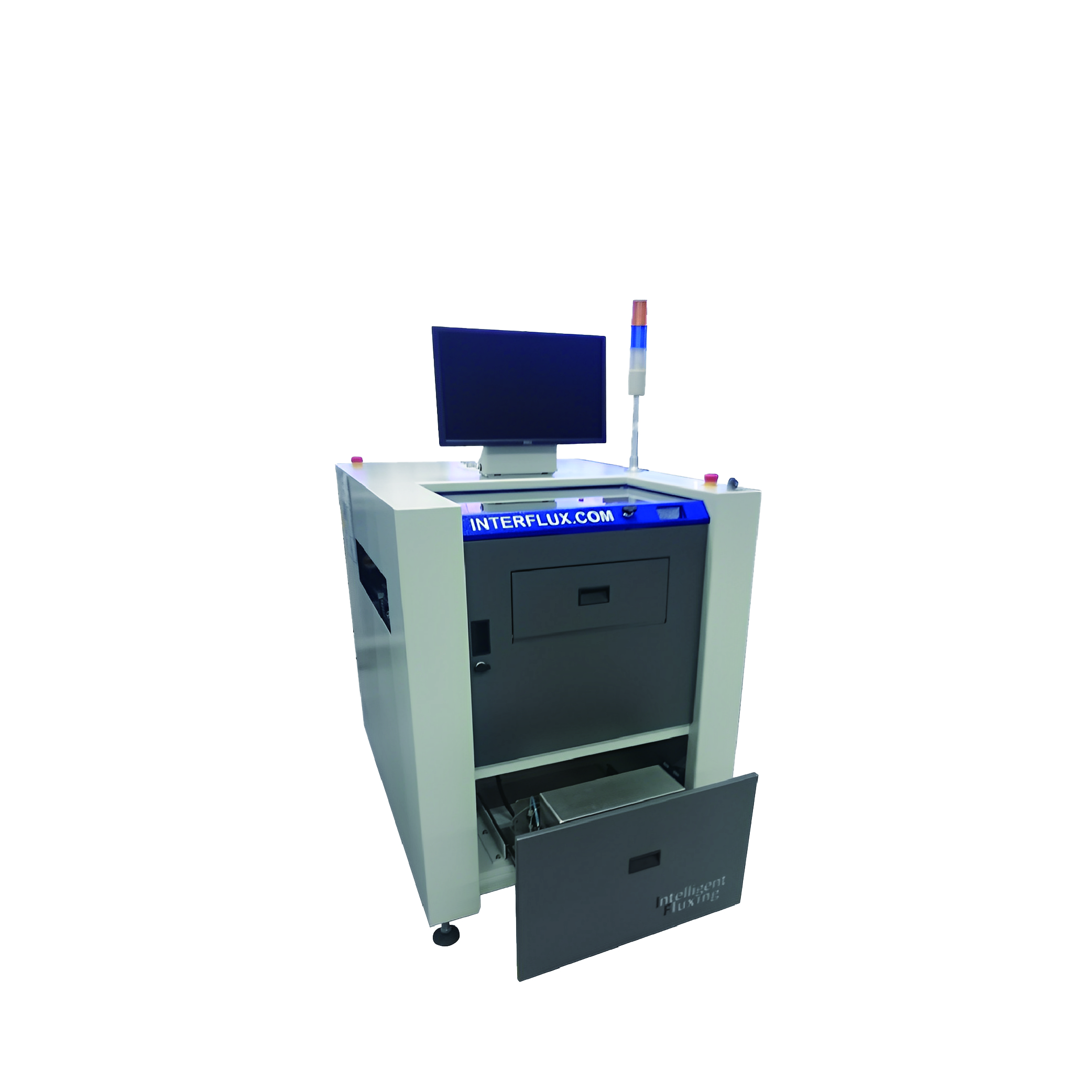

InterFlux ICSF-Select 系列

InterFlux ICSF-Select Series is an innovative selective jetting fluxing machine, which is different with current spray method machine, this will bring quite a lot advantages for the production line and products quality.

- InterFlux ICSF-Select系列设备是一款革命性的助焊剂喷涂产品,独有的Jet喷射技术区别于常规的喷雾式设备,可以提供助焊剂节约、板面污染、提高焊锡质量等一系列优势

|

Items |

ICSF-SELECT 6 |

ICSF-SELECT 4 |

ICSF-SELECT 3 |

|

Conveyor Length |

1,000mm |

850mm |

750mm |

|

Product Size |

610x610mm, Optional 920x610mm |

410x410mm |

310x310mm |

|

Weight |

600 kg |

550kg |

500kg |

|

Machine Frame |

welded |

||

|

Compressed Air Supply |

No Compressed Air used |

||

|

Conveyor Type |

SS316 Pin Chain |

||

|

Conveyor Height |

SMEMA height 930mm ± 30mm |

||

|

Conveyor Width |

Automatic adjustment by software: Max 610mm |

Max 410mm |

Max 310mm |

|

Conveyor Speed |

Incoming/outgoing: 10 to 400 mm/s, (Set separately by software) |

||

|

Pass Through Direction |

left to right / right to left (selectable by software) (NO mechanical change necessary) |

||

|

Product Positioning |

Patented soft stop with 2 step detection by Ultrasonic Sensor (No mechanical Stopper) |

||

|

Safety Relay |

Safety circuit with front and back emergency stop buttons, front and back door with individual feedback to software |

||

|

Exhaust Requirement |

No exhaust necessary, but possibility to connect: Diameter 100mm, 150 m /hour |

||

|

Exhaust Detection |

Differential Pressure Switch with indication on software |

||

|

XY Linear Axis System |

Servo controlled Belt Drive |

||

|

Accuracy |

± 0.25 mm |

||

|

Repeatability |

± 50 m |

||

|

Speed |

Max. 1,500mm/s |

||

|

Nozzle Type |

Jet Fluxer (no Air used), 300 microns hole size, optional 200 microns |

||

|

Nozzle Quantity |

1 Jet Nozzle, optional Double Jet Nozzle for different flux |

||

|

Flux Tank |

Stainless Steel, 10 or 3 Liters |

||

|

Tank Quantity |

1, optional 2 with or without couplings for quick tank exchange |

||

|

Flux Level Detection |

Non contact low level switch for each tank |

||

|

Flux types |

Water based, Water soluble, Alcohol based, Rosin based |

||

|

Maximum Solid Content |

40% |

||

|

Flux Supply |

Patented variable flow, volume and pressure system with supply pump and high speed control valve |

||

|

Flux Pressure |

Variable for each programmed location on the board. Controlled by flux supply pump |

||

|

Flux Flow |

Variable for each programmed location on the board. Controlled by flux supply pump |

||

|

Flux Volume |

Variable for each programmed location on the board. Controlled by high speed flux valve |

||

|

Flux Nozzle cleaning/purge |

Automatic flux nozzle cleaning system by purge |

||

|

Flux Jet Control (Optional) |

Patented flux drop check by laser with auto-purge during flux cycle. Ensures 100% correct application of each drop |

||

|

Nozzle Material |

Non Stick Teflon Nozzle with Delrin/SS316 Body |

||

|

Flux drop size |

1.5 to 15mm (depending on flux type, nozzle and settings) |

||

|

Flux Quantity Measurement |

Accurate measurement by software function. Separate weighing scale is needed. |

||

|

Flux Tank Drain |

Automatic drain of supply system and tank by software function with operator prompts |

||

|

Controller |

PC, windows 10 platform |

||

|

Machine Software |

PLC controlled, can run independently from the PC Software in case PC breaks down |

||

|

PC Software |

Package with on and offline programming, picture editing and machine control |

||

|

Flux Programming Base |

JPEG, BMP, GIF, DXF (CAD or GERBER file possible if converted to an image file) |

||

|

Picture Editing |

Editing software integrated in main software: Four point stretch, Rotation, Mirror, Brightness, Contrast |

||

|

Flux Selection |

Flux database with fluxes, containing default values for programming for each type of flux. Customizable by customer |

||

|

Flux Programming Options |

Dots, Lines, Multi-lines, Areas. Parameters can be set for each individual Dot, Line or Area |

||

|

Flux Programming Functions |

Copy, Paste, Copy with base point, Rotation, Line up, Zoom |

||

|

User Security |

3 levels with personalised users |

||

|

Program Optimization |

Software function to optimize flux point routing |

||

|

Barcode |

Optional, Automatic program selection and download for each board or per batch and traceability |

||

|

Traceability |

Optional, all process values in text file or SQL database |

||

|

Alarms |

Current/History |

||

|

Events |

Alarms/Software/Machine/Security |

||

|

Remote Support |

Teamviewer support available worldwide (Machine and PC software) |

||

Environmentally Friendly

- 友好的环境保护

Cost Reduction

- 节约成本

Higher Reliability

- 提高产品可靠性

Smart Board Positioning

- 智能的产品定位装置

Automatic Flux Detection

- 助焊剂实时监控

High Speed XY – Movement

- 快速的移动速度

On The Fly Mode

- 边走边喷技术